We interviewed Javier Cruz, Technical Manager of Stonesize and TINO Natural Stone. Throughout his more than 40 years of professional experience dedicated entirely to stone, Javier has worked in several leading companies in the marble sector. He has developed his own project of distributing high-end stone in Tangier. Today he explains why Stonesize represents a technological revolution in the field of natural stone.

What is Stonesize?

The evolution and revolution in the context of marble; we achieve pieces of large format that until now were impossible to make in marble of 2 cm

What kind of work are you doing with Stonesize?

Everything. It is having high acceptance in the market because its possibilities are vast. We are currently making floor tiles, bathrooms, large format interior coverings, ultra-light natural stone furniture, naval interior design, unique facades.

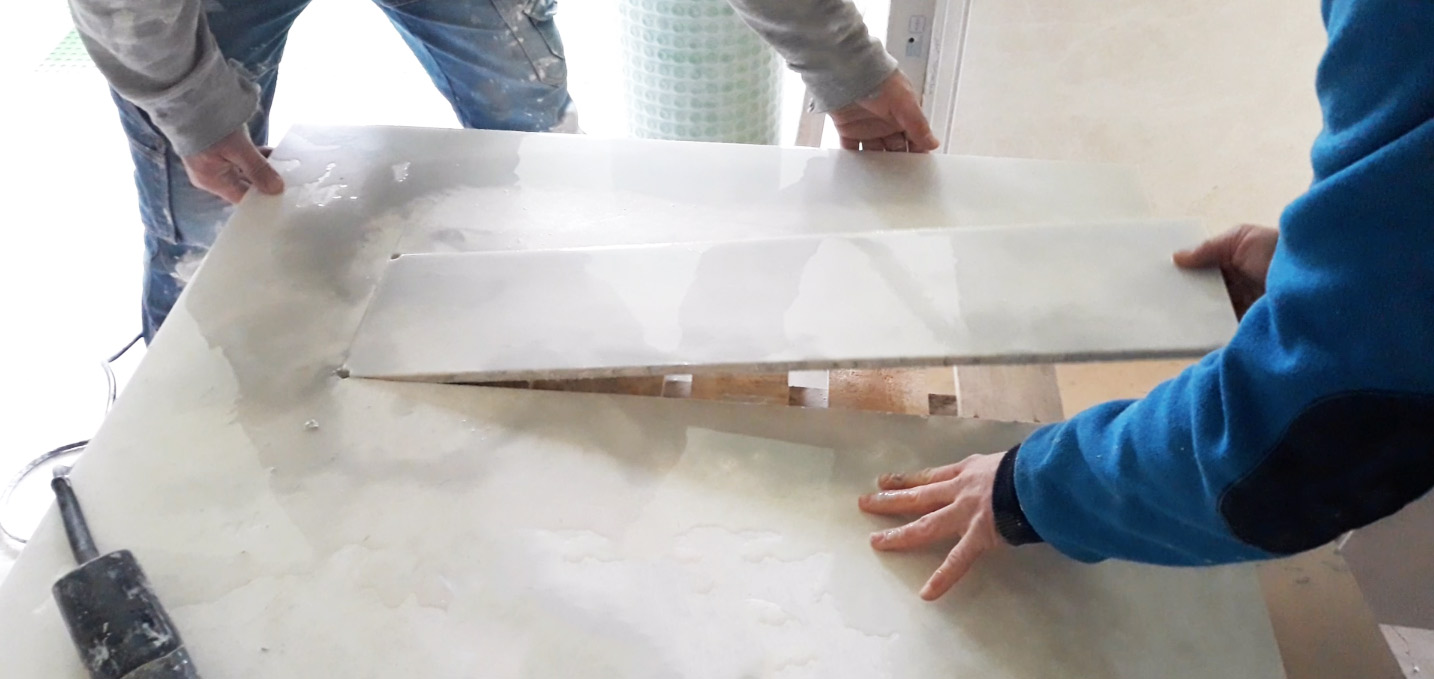

What does it mean from the installer’s point of view to work with ultra-lightweight natural stone panels?

The most important thing is that you know it won’t break. When working with large formats, not all materials are reliable. Many carry a risk of breakage. This risk disappears with Stonesize.

And for the architect or designer who decides to use Stonesize for the project?

For the architect, what is attractive about Stonesize is the full range of possibilities in large format natural stone as we can create pieces of 2900*1450 mm.

Edges, mitered corners, furniture fronts, vein continuation. Is it possible to achieve the same level of finish as with dimensional stone?

Absolutely! I’d say better. When you have to make narrow pieces, there is no risk of breakage. With Stonesize, we can cut strips of 1 cm.

Could you expand on the weight advantages you just told us about? Could you give us an example of a real case?

The advantages are vast, both in flooring and in the veneer. For example, in flooring, we have just placed the entire surface of a bathroom with one piece.

In veneer, more of the same, we are placing pieces of 2900*1400 mm. That is to say, complete walls in one piece and without joints!

In the case of technical floors, what improvement does an ultra-lightweight stone floor introduce?

Hardness and lightness. The tests carried out regarding the hardness are amazing.

You often function as the “technical link” between the designer or project manager of the client company and the factory technicians. What is the role of your department in this regard?

You said it very well: technical link!

We are in charge of transmitting the client’s demands into reality. After making a measurement, we prepare drawings as well as the list of all the parts in “factory” language.

Then, once the parts arrive from the factory, we materialize the customer’s design; no matter how complex it may be.

Could you explain how the small modifications are carried out at the installation site to mold each part to its final location completely?

We have always done this, both with traditional dimensional stone and now with Stonesize. Modifications at the installation site are usually minimal. We prefer to leave it all laid out and very tightly measured in order not to touch anything later. The type of adjustment we make onsite is only that of the boxing. Another advantage of Stonesize is that, in these situations, it cuts and fits much better because it is 5 mm. of marble and not 2 cm.

***