WHAT MAKES STONESIZE IDEAL FOR EXTERIOR COVERINGS?

With the lightweight natural stone panels for facades Stonesize panels we achieve yields never seen before in natural products in the installation of facades. Its great lightness and the ability to manufacture large formats allow to install all types of exterior facades and walls in record time and with the minimum amount of resources. The ideal solution for fast and light architecture.

Facades

One of the best ways to have large formats is Stonesize. Its technology means that we can have pieces of natural stone in formats that were previously impossible.

ADVANTAGES

BIG

LIGHT

FAST

STRONG

REMOVABLE

Lightweight natural stone panels for facades

STONESIZE FACADE INSTALLATION

Stonesize slabs are extremely lightweight and have a very high resistance to impacts, bending and compressions thanks to the use of excellent and innovative materials in the aerospace industry.

Stonesize honeycomb panels, which have excellent technical characteristics, enable extraordinary finishings and are increasingly being incorporated in grand projects by architects and designers. The Anchoring system is suitable for any type of structure for external and internal uses.

FACADE SYSTEM

The integral Stonesize facade system comprises from the Stonesize panels to the substructure system, to provide a global solution for fixing the cladding with the greatest guarantees.

Aluminum is the material most used in light facades due to its shared mechanical properties with a significant lightness compared to other metals such as steel. At the same time it has a good behavior against oxidation, making it suitable for use in facade applications, being economically more attractive than stainless steel solutions.

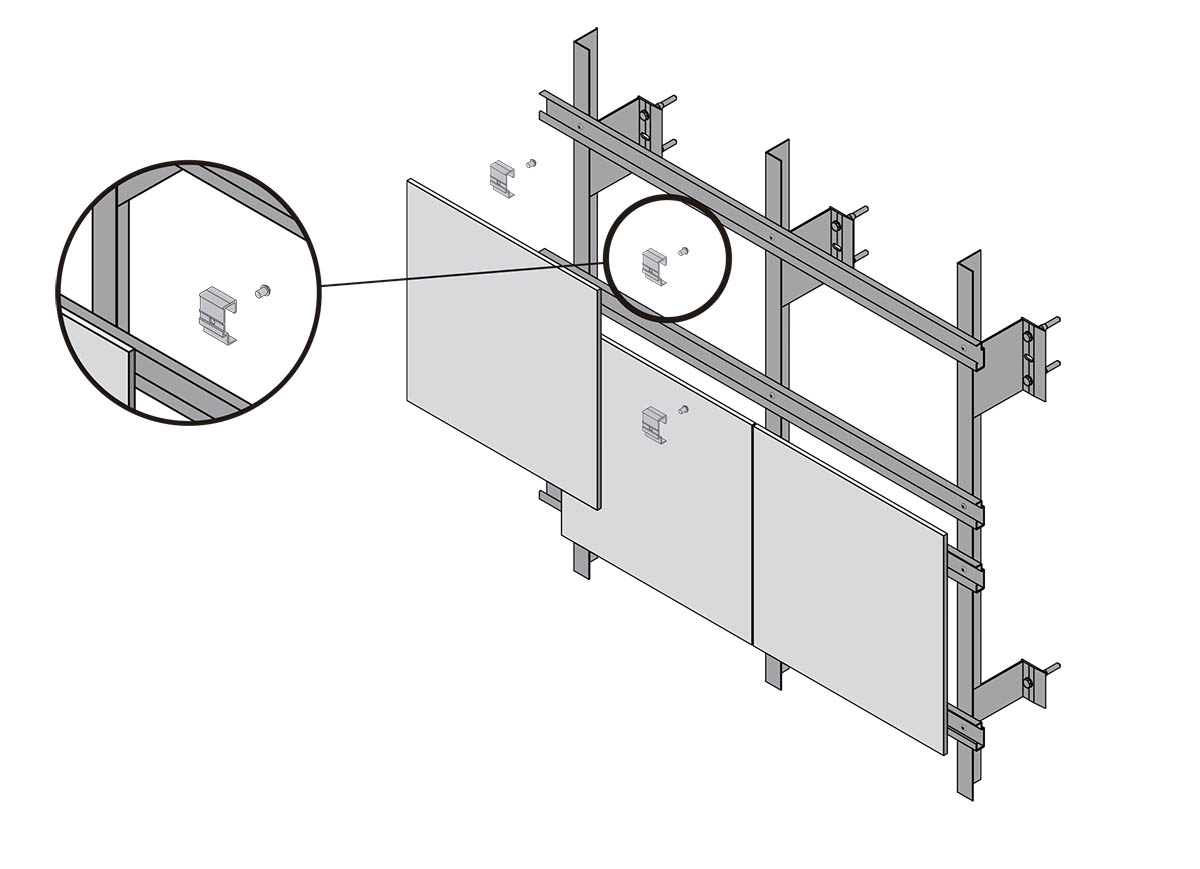

The substructure system consists of vertical profiles that are fixed to the wall using brackets , making it possible to separate the wall covering to include insulation adhered to it to improve energy efficiency and leaving a chamber air for ventilation to occur. These brackets are fixed with anchors to the wall. The connection between vertical profiles and brackets is made with stainless steel screws.

Then, horizontal profiles, also known as hanging profiles, attached to the vertical by screws are fixed.

On the other hand, the hanging clips are attached to the back of each panel, using steel anchor plates that allow them to be joined with sheet metal screws.

Finally, the panels are hung from their clips in the horizontal profiles. There are adjustment screws in the upper clips that allow the panel to be perfectly leveled, as well as fixing screws that hold them against horizontal displacement.

The facillity of handling of the panels is evidently characterized by its low weight. However, the technological effort is not limited to the panel. Tino has developed the StoneSize Integral System in which the panels have a light aluminum substructure system suitable to complete their use in facades with the best guarantees. This substructure has a high ease of assembly since its profiling can be perfectly leveled, thanks to the temporary clamps for the installation of which the brackets are fitted. Once the vertical profiles are plumbed, they are screwed and fixed. Likewise, the hanging system of each panel is equipped with leveling screws to facilitate the perfect execution of each joint between panels.

The facillity of handling of the panels is evidently characterized by its low weight. However, the technological effort is not limited to the panel. Tino has developed the StoneSize Integral System in which the panels have a light aluminum substructure system suitable to complete their use in facades with the best guarantees. This substructure has a high ease of assembly since its profiling can be perfectly leveled, thanks to the temporary clamps for the installation of which the brackets are fitted. Once the vertical profiles are plumbed, they are screwed and fixed. Likewise, the hanging system of each panel is equipped with leveling screws to facilitate the perfect execution of each joint between panels. Honeycomb with stone panel properties are combined thanks to the technology in a composite to provide new and much more powerful properties, reaching an excellent physico-mechanical behavior. This new composite maintains the aesthetics of natural stone while making it suitable for the greater demands of wind loads or earthquakes, without the limitations of the traditional small formats in dimensional stone.

Honeycomb with stone panel properties are combined thanks to the technology in a composite to provide new and much more powerful properties, reaching an excellent physico-mechanical behavior. This new composite maintains the aesthetics of natural stone while making it suitable for the greater demands of wind loads or earthquakes, without the limitations of the traditional small formats in dimensional stone.